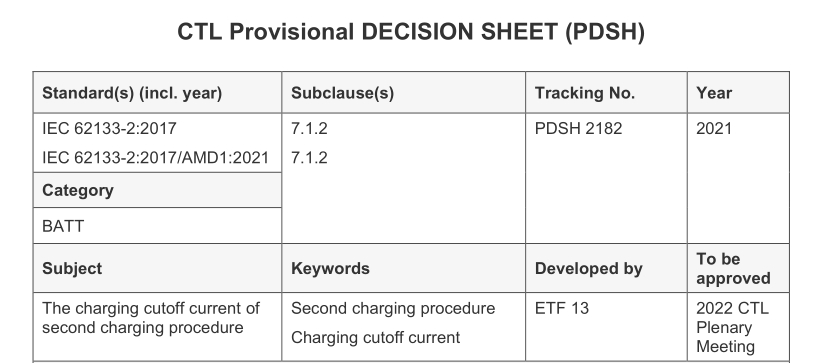

On September 14, 2021, the IECEE International Electrotechnical Commission announced the latest CTL agreement on batteries. The three battery CTL interim resolutions released this time are as follows:

01 CTL Interim Resolution

PDSH 2182: Charging cut-off current

Question: According to IEC 62133-2:2017 clause 7.1.2, the second charging procedure prepared for the test project requires a charging cut-off current of 0.05 It A. When the battery manufacturer defines different charging cut-off currents, which cut-off battery should be used to set the charging conditions?

Answer: 0.05It A should continue to be used.

However, according to the manufacturer's requirements, a set of separate tests can be performed on samples prepared using the manufacturer's defined cut-off current for reference. When charging with the cut-off current specified by the manufacturer, the upper limit voltage of the battery must not be exceeded.

explain:

The charge cut-off current has a great probability of affecting the charging state of the sample and the compliance of the test. Therefore, the value 0.05ItA defined in the standard should be strictly followed. On the other hand, considering that the charge cut-off current designed by the battery manufacturer for its products may be different to reflect the expected use conditions, it is allowed to set separately except for 0.05 ItA. The test of the charge cut-off current is for reference only. According to section 7.1.2, the upper limit voltage of the battery must not be exceeded, regardless of the charge cut-off current value.

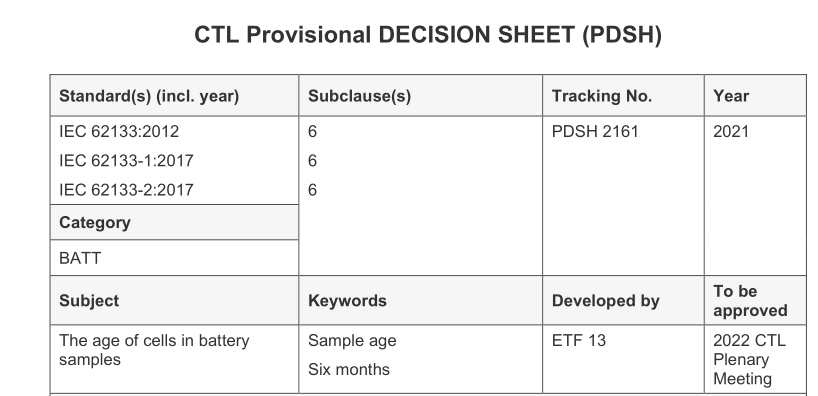

02 CTL Interim Resolution

PDSH 2161: Sample

Question: According to IEC 62133:2012, IEC 62133-1:2017, IEC 62133-2:2017 Clause 6, when evaluating batteries (packs), does the battery cell manufacturing time in the samples require no more than six months?

Answer: Not required.

explain:

IEC SC21A WG4 confirmed that it plans to delete the sample requirement six months ago in the next edition of IEC 62133-2.

Related topics:

Q1: If the battery cell has not been tested separately, it will be sent together with the battery (pack) for evaluation and CB certification. In this case, can the battery manufacturing time be exempted?

A: In this case, a separate full set of tests are required for the batteries, which is suitable for the requirement that the manufacturing time of the batteries cannot exceed six months.

Q2: What needs to be paid attention to when applying for CB certification for battery (package) manufacturers in cross-border supply chains?

A: The cycle of designing and producing batteries (packs) using cross-border purchased batteries may be longer. When the batteries (packs) are made, the battery manufacturing time may have exceeded six months. It is recommended that the cell manufacturer complete the CB certification in advance and provide cell samples and CB certificates. When the battery (pack) manufacturer subsequently performs the battery (pack) CB certification, it does not need to consider the issue of the cell manufacturing time exceeding six months.

Q3: The battery (pack) that has obtained the CB certificate and report needs to be forwarded to other mark certification based on the CB certificate and report. Is the (temporary) decision also accepted?

A: Based on the existing CB certificate and report transfer, it is based on the acceptance of the IEC standard and its CTL (temporary) resolution. However, it is not ruled out that the issuing agencies of different countries or regions have differentiated practices or requirements to issue their own marks.

Q4: Regarding the content of this interim resolution, will you consider directly revising the standard in the future?

A: The IEC SC21A working group WG4 plans to cancel the six-month sample requirement in the next edition of the 1.1 edition of IEC 62133-2.

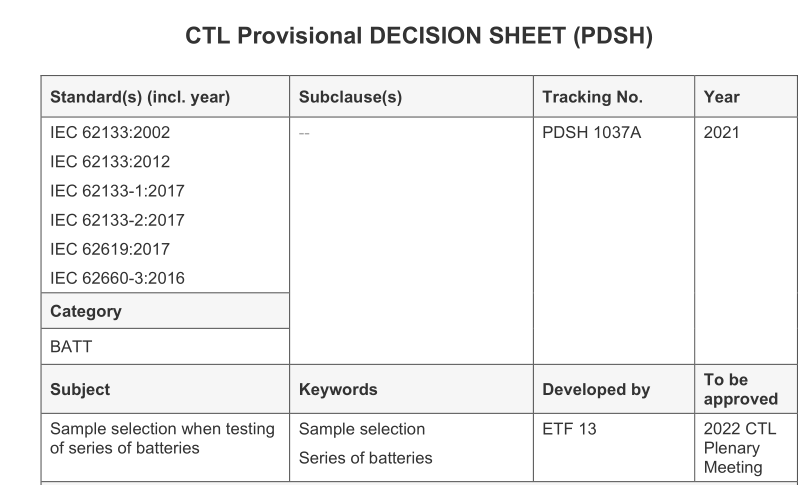

03 CTL Interim Resolution

PDSH 1037A: Selection of series battery samples

Sampling principles for battery series testing:

This interim resolution expanded the battery standards applicable to the original resolution (No. DSH 1037) to include IEC 62133:2002, IEC 62133:2012, IEC 62133-1:2017, IEC 62133-2:2017, IEC 62619:2017 and IEC 62660 -3:2016. In order to facilitate a better understanding, some text adjustments have been made to the content of this resolution.

Question: If a series of batteries of the same size, chemical system, voltage, and capacity are produced by the same manufacturer, if the safety compliance of the entire series is to be verified, which model should be selected for testing?

Answer: In the above example, when the total capacity difference exceeds 20%, start from the highest capacity and calculate the capacity value with an amount lower than 20% of this value. Select those models in the series whose capacity is closest to the calculated value for testing. If the total capacity difference of a series of batteries does not exceed 20%, select the lowest, highest and closest model in the middle of the series for testing. Changes that may cause any test failure shall be considered as new models and shall be subjected to the required tests.

explain:

The type of change that may be considered different from the test type, which may cause any test results to fail, which may include but is not limited to:

(a) The material of the positive electrode, negative electrode, separator or electrolyte has changed;

(b) Changes in protection devices, including hardware and software;

(c) Changes in the safety design of battery cells or battery packs, such as exhaust valves;

(d) Changes in the number of cells that make up; and

(e) The change of the connection mode of the battery cell assembly.

Related topics:

Q1: In response to the requirements of different OEMs, manufacturers need to design soft-packed and square-shaped hard-shell batteries, and their electrical parameters are exactly the same. Can they be tested and certified as a single model or series?

A: Considering that the physical structure of the soft case and the square hard case battery is quite different, and the difference directly affects the related test results and judgments, it needs to be considered as two independent battery projects.

Q2: When there are differences in specific aspects, the battery cannot be tested and certified as a single model or series?

A: The original resolution (No. DSH 1037) standardizes the specific sampling principles. At the same time, it standardizes the main factors that affect the series judgment. If there are the following differences, they are generally not treated as series:

(1) Difference in size

(2) Differences in chemical substances

(3) Difference in voltage

(4) Differences in materials of positive electrode, negative electrode, separator or electrolyte

(5) Differences in protection devices, including hardware and software

(6) Safety design differences of batteries or batteries, such as bleed valves

(7) Cells in series and parallel connection and their number differences, or

(8) Differences in battery cell connection methods.

Based on the strictness of the above specifications and the dangerousness of the battery, during actual testing and certification, the battery is basically a single model.

Related terms:

IECEE International Electrotechnical Commission Conformity Assessment Scheme System

NCB National Certification Body

IEC SC21A IEC Battery Technical Committee

WG4 IEC Battery Technical Committee Portable Battery Working Group

CTL Testing Laboratory Committee

ETF13 Battery Expert Working Group

DSH resolution

PDSH Interim Resolution

Reminder

Under certain specific circumstances, the IEC standard needs to make necessary elaboration, specification or further clarification, and form a CTL (temporary) resolution when necessary. It is recommended that you fully understand and implement the battery IEC standard and CTL (temporary) resolution based on the above discussion.

ZRLK has focused on battery product testing and certification for 15 years, always paying attention to changes in national laws and regulations, and providing customers with one-stop testing and certification services to ensure that your products quickly enter the target market. If you have batteries and battery-containing consumer smart products that need to be tested and certified, please feel free to contact us, our engineers will serve you as soon as possible!